- Cementing Aids

- Straight Bow Casing Centralizers

- Non Welded Hinge

- Non Welded Positive Bow

- Non Welded Integral Bow

- Finned Type Rigid Centralizer

- Solid Body Rigid Centralizer

- Non Welded Hinged Type Straight Bow Turbolizers

- Slip On Glider Spirolizers

- Stop Collars (Lock Rings)

- Cement Baskets

- Scratchers

- Centralizer Assembly Tools

Cementing Aids Casing Centralizers

In 1976, with in-house Research & Development , Laxmi Udyog developed casing centralizers and is the first manufacturer to manufacturer centralizers in India. Laxmi Udyog also got first API license in world for cementing aids bearing license number API 10D-001. With over 3 decades of experience, consistent learning and developments we bear capability to exceed quality to that as per API Specs.

Laxmi Udyog Centralizers are best in class in terms of design, performance, quality.

Wide range of Casing Centralizers offered by Laxmi Udyog are :

Selection Criteria for Centralizer Type (Bow or Rigid)

Straight Bow Casing Centralizers

Non Welded Straight Bow Casing Centralizers

These centralizers are not optimized for open hole casing size combinations so they tend to be less expensive than other types.

Available from 4-1/2” size through to 30” casing size.

Features, Advantages & Benefits

Welded Straight Bow Casing Centralizer

Welded Straight Bow Casing Centralizers

LAXMI welded Casing Centralizers bow design is similar to Non Welded Hinged type Centralizer but in this type of Centralizers bows are welded to the end collar to provide superior strength. The bows are strongly welded to end collars with correct grade electrode to ensure desired performance of centralizer under load.

These Centralizers are available in Slip on and Latch on type configuration. The Latch-on Hinged type also feature integral hinges, which folded inside thereby minimizing collar stretch. Welded bow centralizer can be supplied in straight, spiral and positive configuration. All specification dimensions are same as non - welded Centralizers but have strength exceeding then that of Welded Centralizers.

Features, Advantages & Benefits

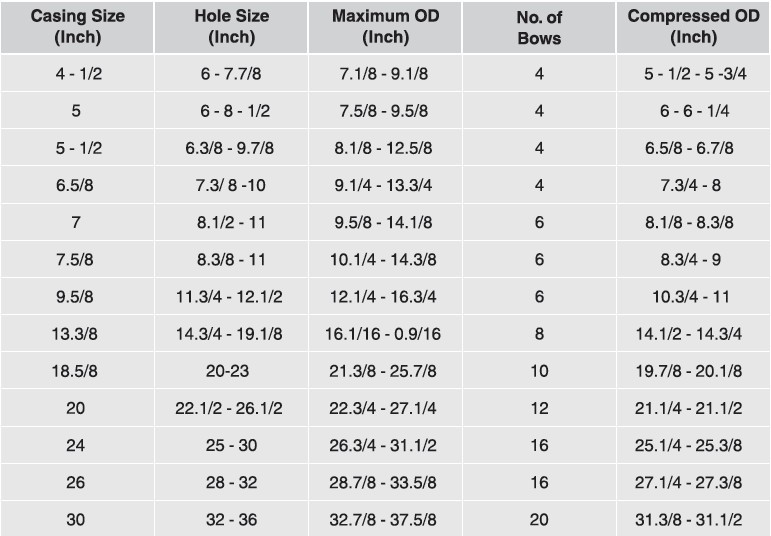

Specification of Welded & Non Welded Straight Bow Casing Centralizers

Non Welded Hinge Type - Semi Rigid Double Bow Spring Casing Centralizers

Semi Rigid Double Bow Spring Casing Centralizers

The Bows are manufactured from double rolled, uniformly heat treated spring steel which are adjoined to end collars by pushing lips.

These centralizers are ideally suitable for running in horizontal or highly deviated wells.

They are available in sizes 41/2” to 20 “ casing sizes. Special sizes are available of request.

These type of centralizers are available for both Welded & Non Welded makes.

Features, Advantages & Benefits

Non Welded Positive Bow (RIGID) Casing Centralizers

Non Welded Positive Bow

These Centralizers are used where Casing inside a cased well is lowered. It keeps the casing centered in the cased. It protects previously run cemented casing from shocks and vibrations caused by drilling. The outside diameter of the bows are kept 1/4" smaller then the cased well bore that they are being run into. These include the reduction in drag associated with running pipe in deviated and horizontal wells. These Centralizers are designed to be installed between Stop Collars or free floated on the Casing.

These type of centralizers are available for both Welded & Non Welded makes.

These Centralizers are available in sizes from 5-1/2" through to 20" casing size.

Features, Advantages & Benefits

Specifications of Welded & Non-weld Positive Centralizers

Non Welded Integral Bow Centralizer

Non Welded Positive Bow

These Centralizers have high restoring force with zero starting force & zero running force, And also offer high fatigue strength for axial forces and radial side loads on bows during tubular rotation.

It gives good performance in open hole and in cased hole. This type of Centralizer meets or exceeds API specifiction 10D.

These Centralizers are used to keep the casing in the center of well bore in vertical devited and horizontal wells.

The single piece spring bow Casing Centralizers are available in sizes 41/2" to 13 3/8".

Features, Advantages & Benefits

Specification of Welded Straight Bow Casing Centralizers

Finned Type Rigid Centralizer

Non Welded Positive Bow

These centralizers can be used with Liner Hangers slim hole environment & close tolerance drift diameters. They are used in conjunction with stop collars to correctly locate them on the casing.

Finned Centralizer are made in various lengths as per customer requirement.

Features, Advantages & Benefits

Specification of Finned Type Rigid Centralizers

Solid Body Rigid Centralizer

Non Welded Positive Bow

Solid Body Rigid centralizers are available in Alloys of Aluminum, Zinc and Steel. Each alloy of material has its own characteristics such as the acid resistance, lightweight handling and anti corrosive properties.

Our Special Aluminum Alloy Solid Body Rigid Centralizer are light weighted and have high tensile strength, High impact strength and shock resistance properties and can effectively work in operational temperatures up to 500º F.

The product is available in Alloy of Aluminum, Zinc and Steel in Size Form 3½” to 13.3/8” Casing. It can be manufactured with straight blade or spiral blade with left or right hand flow.

Features

Specification of Solid Body Rigid Centralizers

Use of Spiral Solid Centralizer

# To obtained maximum stand off the spiral solid centralizer can also be run in conjuction with the Solid Straight Blade Centralizer

Choice for a Solid Spiral Centralizer

Advantages

The LAXMI Solid blade Centralizers provide many advantages to ensure easy well bore entry, clean fluid passes and maximum Casing / Well bore stand off.

Maximum Horizontal Stand Off

Smooth design and reduced drag while running a horizental assure greate success in reaching T.D.Reduced Drag & Gouging

The Casing gets a smooth bore sled ride into the well bore reducing casing wall contact & differential sticking.Maximum Stand Off

Solid Centralizers are designed for more then 90% stand off allowing fluid velocities to be almost equal around the pipe.With Stands literal forces

Solid Centralizers ensure a fixed stand off regardless of lateral forces, which is not possible in the bow centralizers.Placement of Solid Centralizers on Casing

Space 20 feet Apart (2 per joint) between two stop rings or a coller and a stop ring, centralizer should run without set screw. Space 2 per joint with a stop ring between the middle of the coupling joint.

Space 2 per joint 20 feet apart screwed with the centralizer set crew. A stop ring may be placed in between for added no slipage. Spiral Centralizer have no set screw and must be run between stop rings. It is recommended that spiral centralizer never be anchored to the casing with set screew because of the scrapping action .

On well bores with angle build-up 4º /100 feet and above, run only 1 short solid centralizer per joint between stop rings.

On collared casing, 1 per joint does not need a stop ring but 2 per joint needs a stop ring between the centralizers.

Note : Spiral Centralizers should always be allowed to rotate freely on the casing.

Non Welded Hinged Type Straight Bow Turbolizers

Non Welded Positive Bow

Turbolizer are available in the same sizes and bow height as straight bow Casing Centralizers.

Laxmi Udyog manufacturers two types of Turbolizers; Single Bow Turbolizer which have one blade on each bow and Double bow Turbolizer which have two blades on each bow. Both blade are oriented in opposite direction.

Turbolizer are available in the same sizes and bow height as straights bow Casing Centralizers. Turbolizer blade are supplied in left hand or right hand direction.

Features, Advantages & Benefits

Slip On Glider Spirolizers

Non Welded Positive Bow

Slip on Glider Spirolizers can be manufactured in both Straight blades and Spiral blades designs.

Slip on Spirolizer can easily fit on casing by inserting from one end of casing pipe. They are spiral & straight blade type Spirolizers. Spiral blade design are used where hole cleaning and better cement placement with minimum pressure drop is required.

Features, Advantages & Benefits

Specification of Slip on Glider Spirolizers

Stop Collars (Lock Rings)

Lock Rings

Latch On Bolted Type

Hinged Type Latch On Stop Collar With Spiral Pin & Nail

Latchon Setscrew Type Stop Collars

Slipon Setscrew Type Stop Collars

Slipon Beveled And Screw Type Stop Collars

Slipon Set Screw Aluminium Stop Collar

Cement Baskets

Cement Baskets

Metal Petal Basket

Canvas Type Basket

Canvas is fitted in side of bow with overlapping. This type of Basket is Slip on type & easily installed by sliding it over the pipe and of casing joints. Baskets are available in wide range of casing size (4-1/2" to 20") to hole sizes and it self-centering due to its sturdy spring steel bows. Design is as such Basket have minimizes interference against casing for assisting pipe rotation and reciprocation.

Specification of Cement Basket

Scratchers

Reciprocating Casing Scratchers

Rotating Casing Scratchers

Centralizer Assembly Tools

Recommended Assembly Procedure Of Non-Weld Casing Centralizer

Explanation

Developed by Tactilesense & Technologies Pvt Ltd